ASSET DESIGN AND BUILD

"Are our assets and processes designed to enable the most efficient production and life cycle cost?"

In the design phase already focus on failure avoidance and elimination, design potential failures out.

Include "Total Cost of Ownership" (TCO) as one of the design criteria. Focus on technical solutions, engineering standards and standard operating procedures.

Include "Total Cost of Ownership" (TCO) as one of the design criteria. Focus on technical solutions, engineering standards and standard operating procedures.

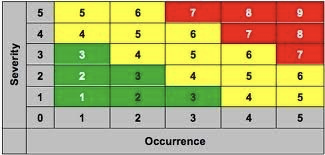

ASSET VALIDATION AND TOTAL RISK RANKING

"Did we identify the potentail risk at asset failure and evaluated the consequences of functional failures?"

Ensure ALL maintainable assets present are know, documented and details available

Check / Investigate the real impact and consequences of all possible asset or process failures. including likelihood and detectability.

ASSIGN AND IMPLEMENT RELIABILITY STRATEGIES

"Did we implement the correct maintenance and reliability strategies to avoid or limit consequences of failure?"

Apply actions, based on risk, and precautions to ensure risks are mitigated or at least the consequences are limited to acceptable proportions

Documentation with asset, timeline/ frequency and details readily available”

ASSET CARE (MAINTAINING ASSETS)

"Do we maintain our assets in the best manner and did we include feedback loops to enable cycles of improvement?"

Use the assigned techniques at the pre-set time….Do the Right thing at the Right moment

Use a thorough Feedback and Follow-up process to capture experiences in order to improve overall performance.